Concrete Driveway Installation Process for Paterson Homes

Concrete Driveway Paterson

In Paterson, installing a concrete driveway is a multi-step process (typically taking weeks) that begins with careful planning, proper permits, and compliance with the state of NJ’s construction codes. Knowing what to expect at each step will help homeowners plan their project and have reasonable expectations as to how long it will take. Weather can be a major factor in scheduling projects in NJ, especially during the winter months when working with concrete can become difficult. A professional contractor coordinates all of the steps involved so that your project gets done on time and remains durable over time.

Pre-Construction Planning and Permit Phase

In order to start planning for any type of concrete driveway project, you will need to obtain the necessary permits from Paterson’s Construction Code Enforcement agency. Permits in Paterson usually take 3-5 working days to get approved, depending upon how complex the project is and how many applications are currently being processed. Contractors will have to submit detailed plans showing size, setback from surrounding property lines, and drain conditions for driveways located close to other developments such as East Side Park or the central business district of Paterson. In addition, all municipalities will need to be up-to-date on their taxes before permitting, which will need to be confirmed by the Tax Collector’s office. A professional assessment of the current condition of your home will also assist you in identifying possible obstacles that may affect your project schedule.

Design and Site Assessment Finalized

Once an experienced contractor has conducted an exhaustive site analysis to determine the soil composition, drainage characteristics, and the accessibility of the location, they will then measure the distance from the edges of your lot to nearby structures (such as your garage or sidewalk) and map out the locations of underground utilities to avoid conflict during the excavation process. Homeowner preferences for thickness, rebar placement, and finishing options will be incorporated into your driveway design to ensure it matches your aesthetic expectations. The details of your project will provide accuracy in the purchase of the required materials and minimize the risk of delays during the construction process.

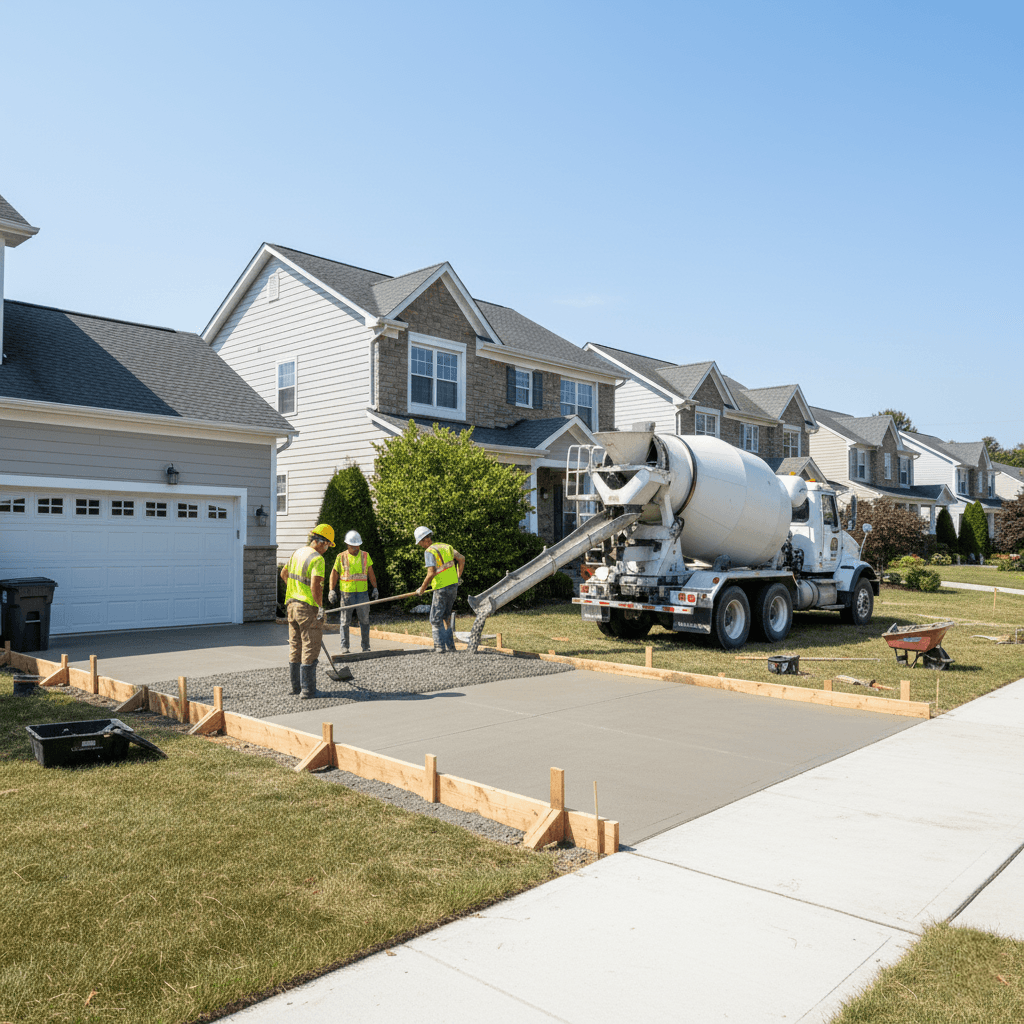

Driveway Excavation and Preparation of the Subgrade

The typical duration for the excavation of your driveway is one to two days, based on the total area of the job and the amount of previous pavement or debris that will need to be removed to allow for the installation of the new driveway. A professional crew will remove any previous concrete, asphalt, or landscaping that may be present in the area to achieve the correct depth for your new driveway. Once the subgrade has been prepared, the contractor will compact the dirt beneath your driveway using specialized equipment to create a uniform surface that meets the engineer’s specifications. Driveway designers will consider the proper drainage characteristics for your driveway to ensure that water does not collect next to structures such as the historic buildings of the Great Falls Historic District, which would potentially shorten the life of the driveway. The contractor will also construct the proper forms and grade the driveway so that water will flow away from your home.

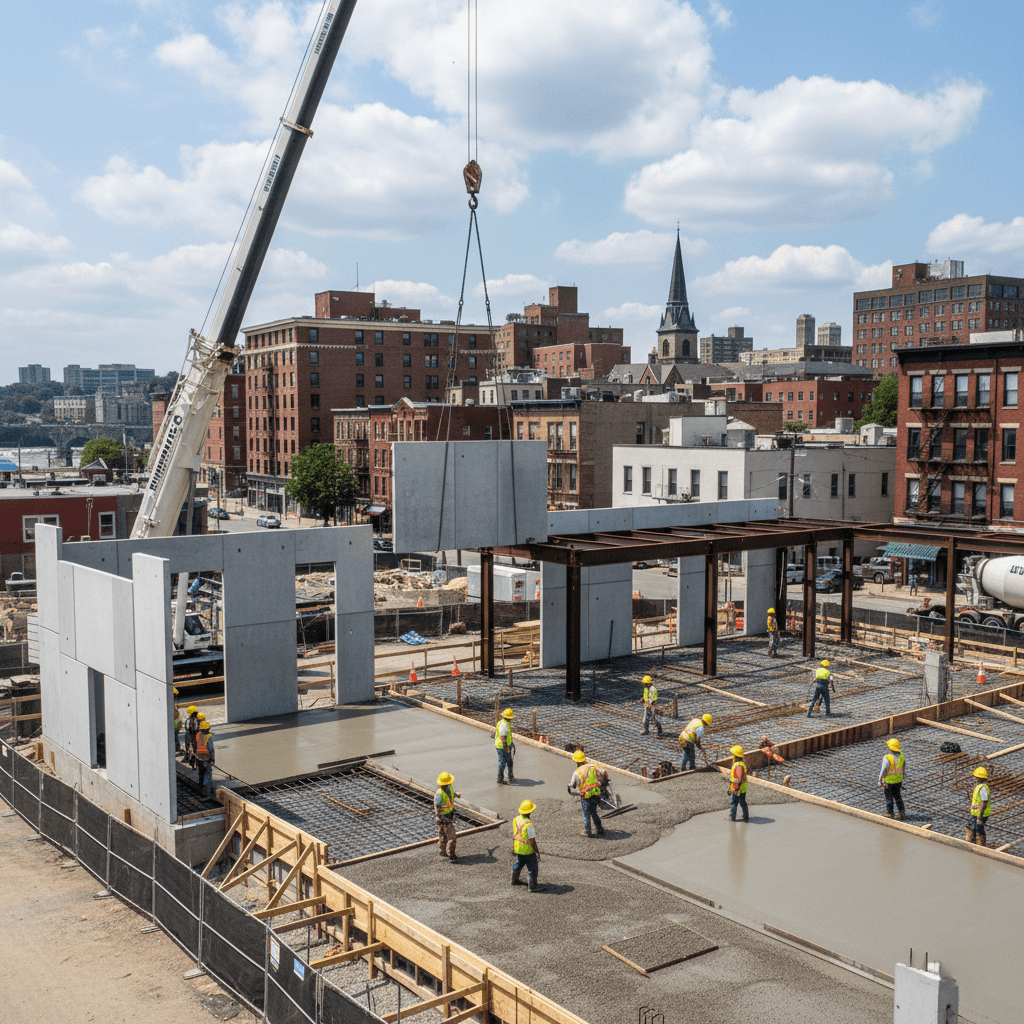

Installation of Base Materials and Compaction

High-quality base materials (modified stone or gravel) are used to add support to the concrete driveway. The base course is usually 4-6 inches in thickness and must be mechanically compacted to develop the proper density. To ensure that the base material is uniformly compacted across the entire surface area, the contractor will utilize specialized equipment. Proper base preparation will eliminate the possibility of settling or cracking of the finished driveway. Reinforcement materials (wire mesh or rebar) will be installed after the base course has been prepared.

Pouring the Concrete and Finishing

Pouring concrete for the driveway is the single most critical step in the installation of your driveway. The contractor will arrange for the delivery of the concrete to ensure that there is no interruption in the pouring process, thereby preventing the formation of “cold joints” that can weaken the structural integrity of the driveway. The contractor will employ various concrete finishing techniques (screeding, floating, etc.) to produce the desired appearance and functionality of your driveway. Weather conditions can significantly impact this step of the process, as pouring should not occur at temperatures less than 50°F or greater than 90°F, unless precautions are taken. Teams will work diligently to complete all finishing operations before the initial setting of the concrete.

Quality Control and Initial Curing

Immediately following the completion of the installation of your driveway, quality control measures will be performed to inspect the installation for proper thickness, surface level, and drainage slopes throughout the installation. Protective cures or coatings will be applied to the surface of the concrete to maintain optimal moisture levels throughout the critical early hours of the curing process. Protecting the surface from the elements during the initial curing phase is essential in Paterson’s unpredictable weather conditions throughout the year. Proper curing methods will enable the concrete to achieve the intended strength and durability.

Cleanup and Equipment Removal

Following the completion of all curing protection measures, the contractor will remove any equipment and clean up the site.

Curing Schedule and Access Restrictions

Understanding the curing time of concrete enables homeowners to make plans for temporary parking arrangements and access restrictions. Optimal curing temperatures range from 50-75°F for best results in New Jersey’s climate. Initial surface hardening typically occurs within 24-48 hours, enabling careful foot traffic but prohibiting vehicular access. Pedestrian access is typically safe after 3-4 days when surface strength has reached adequate levels. The contractor will monitor the curing process to ensure that it progresses normally prior to allowing further access.

Access to Vehicles and Maximum Strength Development

Vehicle access for standard passenger automobiles is typically allowed after 7 days when the concrete has achieved approximately 70% of its design strength. Trucks carrying heavy loads (delivery trucks, SUVs, etc.) typically require longer waiting periods (14-28 days) dependent upon the specifics of each load. Complete design strength development typically takes 28 days under ideal conditions; however, concrete continues to gain strength over several months. Contractors will provide homeowners with explicit information regarding weight restrictions and edge protection during the initial curing phase. Contractor oversight will provide homeowners with guidance for caring for their driveways to promote long-term durability.

Weather Conditions and Scheduling During Seasonal Time Frames

Seasonal weather conditions in Paterson greatly affect project scheduling and concrete performance throughout the installation process. Generally speaking, spring and fall seasons offer the most desirable conditions with moderate temperatures and relatively low humidity for consistent curing. Summer projects require extra precautions to prevent rapid moisture loss and extreme heat, both of which can negatively affect the surface quality of the concrete. Winter projects experience difficulties due to freezing temperatures, which stop the curing process and require protective measures. Contractors continually monitor weather forecasts to schedule the most critical phases during the most favorable weather conditions.

Protection of Cold Weather Installations and Heating Methods

If a contractor is installing a driveway in cold weather, they may need to utilize heating methods, insulated blankets, or accelerating admixtures to maintain the proper temperature for curing. Contractors will take protective measures to prevent freeze damage to the driveway during the vulnerable early stages if the ambient temperature drops below 40°F. Longer curing times are required if the ambient temperatures remain consistently low throughout the process. Snow and ice removal methods will protect recently installed surfaces without damaging them. Experienced contractors will modify their project schedules according to the seasonal challenges and still meet the quality standards.

Inspection of Completed Projects and Project Conclusion

Inspectors from Paterson’s building department will evaluate the completed driveway installation to confirm that all installation phases comply with local building codes and project specifications prior to declaring the project complete. Contractors will perform a thorough quality examination, including thickness checks, evaluation of the finished surface, and drainage tests to verify that the finished driveway was constructed according to the project specifications. Any necessary modifications or touch-up work will be completed before issuing the final approval and activating the warranty. Documenting all phases of the project will provide homeowners with a complete record for future reference.

Guidelines for Maintenance and Long-Term Care

Contractors will provide detailed maintenance guidelines to homeowners to help them preserve their investment and extend the life expectancy of their driveway. Initial maintenance recommendations include avoiding the use of de-icing products during the first winter and limiting heavy loads on the driveway during the first year. Regular cleaning and periodic seal coating will help protect the driveway from New Jersey’s freeze-thaw cycles and chemical exposure from road salt. Early detection of small problems will eliminate the possibility of expensive repairs and maintain the driveway’s appearance. At Paterson Concrete Works, we provide all of our residential customers with detailed maintenance instructions and ongoing support to maximize the performance and longevity of their concrete driveway investment.