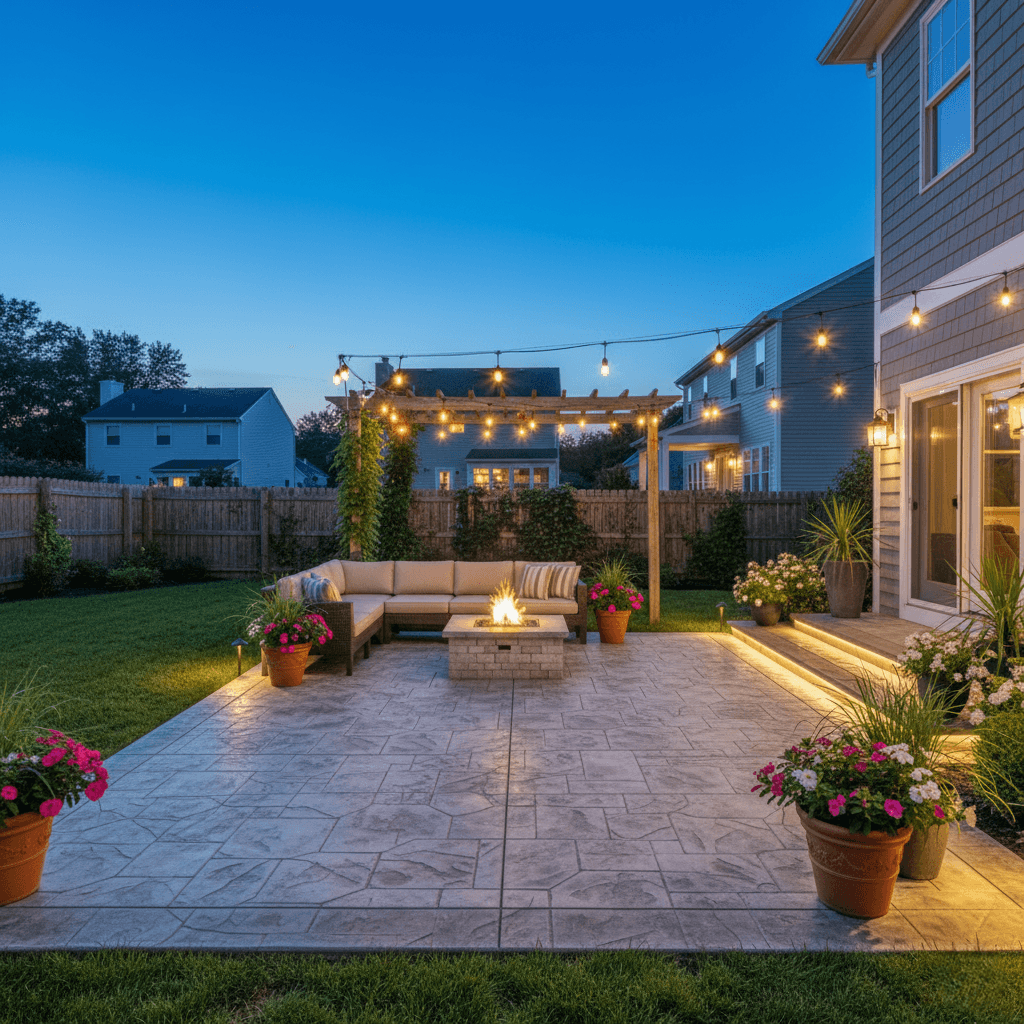

Step-by-Step Guide to Installing a Concrete Patio in Paterson, NJ

Concrete Patio Paterson

Building a concrete patio is complex and will require detailed planning, in addition to abiding by local building codes, if you want to be certain your project is completed successfully. The patio installation process includes several phases from planning to curing of the concrete, which can generally take two to three weeks, depending on the weather. Familiarizing yourself with Paterson’s local building permits and other construction regulations, you will be able to avoid costly delays or violations when completing your patio installation. When installing your patio professionally, it will allow for adequate drainage, the structural stability of the patio, as well as its overall durability in New Jersey’s severe climate. Additionally, professional installation also assures that your patio will be an attractive area to live outside of your home and will increase the value of your property.

Permits and Planning Requirements for Your Concrete Patio Project

The first step to completing a successful concrete patio project is obtaining the proper permits from Paterson’s Construction Code Enforcement Department, located at 111 Broadway in Paterson. These permits will need to detail the plan you have for your patio, along with your setback requirements, drainage considerations, and other important elements to the city. If your patio exceeds 500 square feet, you may need to obtain a grading plan and possibly undergo an engineering review before receiving your permit. In addition to obtaining your permits, you must also verify that all of your back taxes are paid up before receiving your permit, which can be done via contact with the City of Paterson’s tax collector. It is also beneficial to communicate with your neighbors regarding your project timeline to maintain positive working relationships throughout the construction process.

Assessment and Design Planning

Once you have obtained your permit(s), it is essential to perform a professional site assessment to determine your soil’s condition, drainage pattern, and best location for your patio relative to your home’s existing structure. Your design will consider several different factors, including but not limited to sunlight exposure, accessibility to your home, and integration into your existing landscaping (in areas such as Riverside or Totowa). Furthermore, the site assessment will identify potential utility conflicts to avoid problems during the excavation phase of your patio construction project. Planning the right thickness for your concrete, reinforcing options, and finishing techniques are also important considerations. Establishing a clear boundary for your project will allow your contractor to provide you with a more accurate estimate of the materials needed and a more reliable timeline projection.

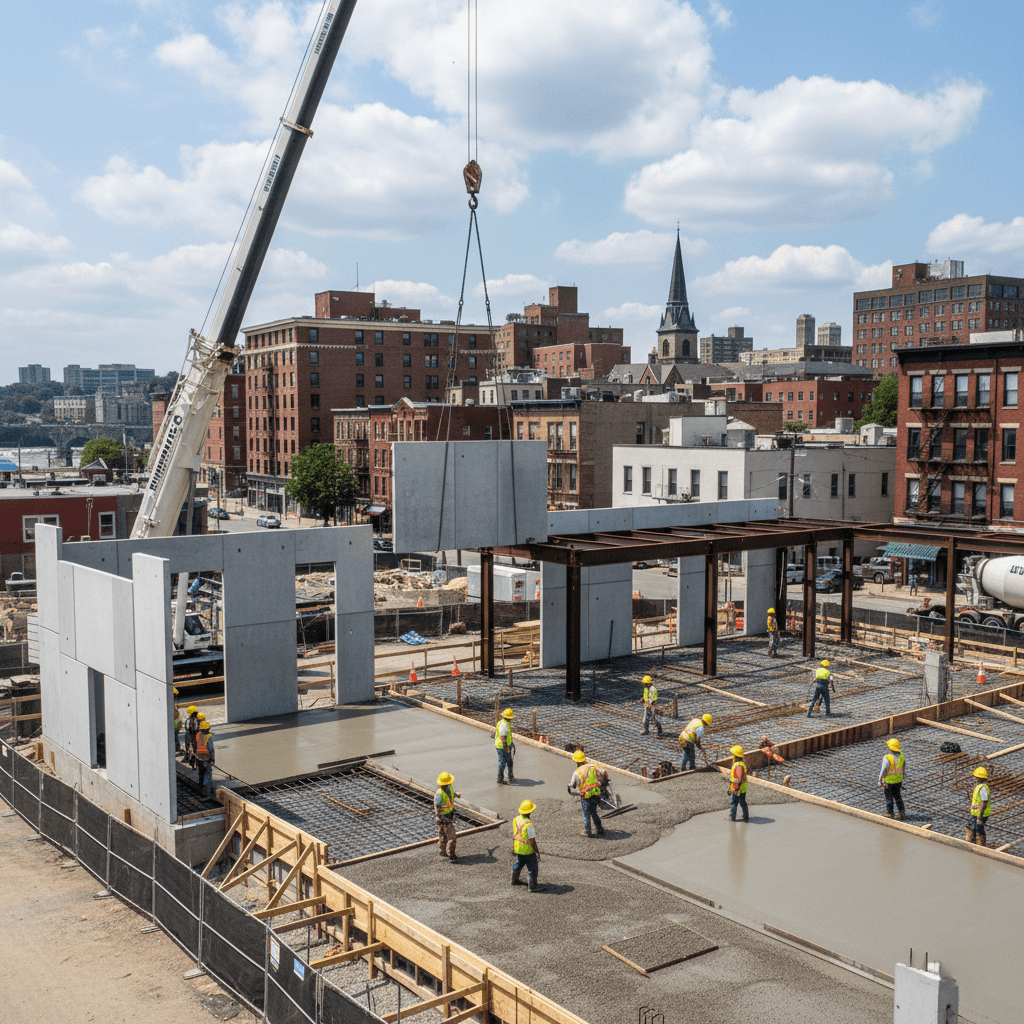

Preparation and Excavation

Upon receiving your permit(s) and conducting your site assessment, your site preparation will commence by identifying your utility lines and creating accessible pathways for equipment and material deliveries. The average patio excavation depth is typically around 6 to 8 inches in order to allow for the base material and the required thickness of the concrete for your patio. Professional concrete contractors will remove existing vegetation, topsoil, and any other organic material that could potentially affect the structural integrity of your patio’s foundation. Once your site has been prepared, your contractor will grade your site to create the proper slope for water to drain from your home and towards a collection point. Your contractor will also take steps to protect the surrounding landscaping and structures during the excavation portion of your project.

Installation of Base Materials and Compaction

When installing the base materials for your patio, professional contractors utilize high-quality materials that are clean and angular to provide a solid foundation for your concrete patio. The typical base layer is approximately 4 inches deep and must be mechanically compacted in 2-inch layers to achieve the correct density. Contractors typically use either a plate compactor or a vibratory roller to uniformly compact the entire patio area. Properly preparing the base of your patio will eliminate potential settlement and cracking of the finished surface. Edge restraint and form installation occur once the base material is compacted and confirmed.

Forming and Reinforcement Installation

Using straight lumber or metal forms, professional contractors establish clean and precise edges for the concrete installation. Your forms must be level, properly braced, and securely fastened to prevent movement while your concrete is being placed. Contractors will install expansion joints strategically throughout the patio to control cracking due to thermal expansion. Contractors will utilize one of the many reinforcement options available, including wire mesh, rebar, or fiber additives, to increase structural integrity and improve crack resistance. By placing your reinforcements properly, you will also ensure you have sufficient concrete cover to prevent potential corrosion issues over time.

Final Grade Check and Drainage System Installation

After verifying the final grade of your patio, you can confirm the proper drainage slopes and elevation differences relative to the surrounding structures. Prior to delivering the concrete, your contractor will prepare all of the necessary tools and equipment for the concrete placement and finishing operations. Your contractor will set up the necessary drainage systems, if required, using French drains or surface channels to direct water runoff. By inspecting your forms and reinforcement prior to pouring the concrete, your contractor will minimize the possibility of costly corrections during the concrete placement operation. Your contractor will also prepare your tools and equipment to facilitate a timely and efficient concrete placement and finishing process.

Mixing and Placing the Concrete

Your contractor will mix the concrete to produce the correct water-cement ratio and admixtures to ensure maximum strength and workability. Coordination of your concrete delivery and finishing crews will be necessary to ensure the timely placement of the concrete throughout the pour. Your contractor will monitor both the concrete temperature and slump to ensure compliance with specification requirements and weather conditions. Proper placement techniques will involve a sequential pouring pattern to eliminate potential cold joints and provide a uniform thickness. Upon placement of the concrete, your contractor will begin screeding and initial leveling to establish the proper surface elevations.

Finishing and Texturing the Surface

Screeding and floating will be used to create a smooth, level surface free from voids and imperfections. Depending on the design requirements of your project, your contractor will apply the desired texture to the surface, including but not limited to broom finishes, stamped patterns, or exposed aggregate. Timing is crucial as the finishing operations must be performed within specified time frames relative to the concrete setting times. Properly cutting the edges and joints will create a clean and professional appearance while limiting crack locations. Upon completion of the finishing operations, your contractor will inspect the surface to ensure it meets the quality standards established for your project before commencing the curing process.

Curing Process and Protection

During the curing process, your contractor will ensure proper moisture and temperature conditions to optimize strength development in your concrete over the course of the next 28 days. During this period, your contractor will apply a curing compound or cover the surfaces with plastic sheeting to prevent excessive moisture loss from the concrete. Due to the extreme weather conditions found in New Jersey, your contractor will implement protective measures against extreme temperatures, winds, and precipitation. Throughout the critical curing phase of your project, your contractor will closely monitor the progress of the curing process while maintaining the quality of the surface. Proper curing techniques will directly influence the long-term durability and appearance of your completed patio.

Restrictions on Access and Timeline Management

Access restrictions will begin immediately after the concrete has been placed, and foot traffic will be restricted for a minimum of 24 to 48 hours, depending upon weather conditions. Light pedestrian traffic will generally become acceptable after 3 to 4 days when the surface strength has reached acceptable levels for cautious walking. Normal usage of the patio and furniture placement should be delayed until the surface strength has increased sufficiently (typically 7 to 14 days) to prevent potential damage to the surface or impressions. Your contractor will provide specific guidance on weight restrictions and care procedures during the initial curing process. Patient waiting during the curing process will result in optimal long-term performance and appearance of your completed patio.

Final Inspection and Quality Control

Guidelines for Maintenance and Long-Term Care

By providing homeowners with recommended maintenance guidelines for their newly installed patio, your contractor can assist homeowners in maintaining their investment and extending the life of their patio by performing routine maintenance and repair tasks. Recommended initial maintenance actions include refraining from using de-icing chemicals during the first winter and protecting your patio’s surface from potential impacts or sharp objects. Periodic cleaning of your patio’s surface with mild detergents and occasional sealing of the surface will help protect your patio’s surface from staining and damage caused by weather in New Jersey’s climate. Early detection of minor issues will prevent costly repairs and maintain your patio’s appearance for years to come. At Paterson Concrete Works, we offer comprehensive installation services for residential concrete installation projects to provide our customers with the best possible results for their new patio and to enhance their outdoor living experience for years to come.