When Does a Concrete Surface Need Resurfacing in Paterson?

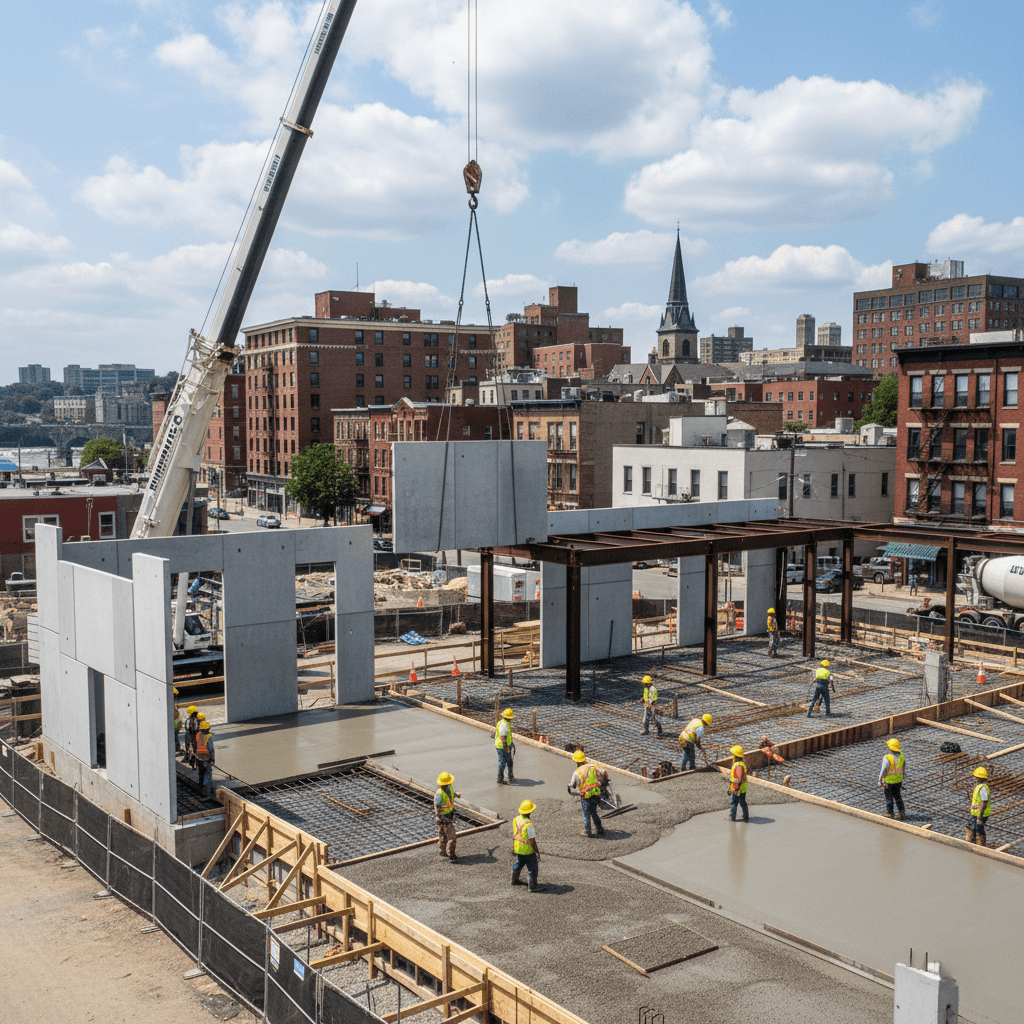

Concrete Resurfacing Paterson

Identifying at what time a concrete surface should be resurfaced in Paterson, NJ, is based on identifying the specific types of damage to the surface and the signs of deterioration which would indicate that it will need to be repaired. Concrete resurfacing, as opposed to replacing it entirely, is an effective method for repairing surface wear, minor structural problems, and cosmetic issues with a lower overall financial commitment than total replacement. When assessing when to resurface, homeowners are able to help protect their property values by taking care of potential damage before it progresses to the point where they have no option but to spend a lot of money to rebuild. When deciding if a concrete surface should be resurfaced or replaced, a professional evaluation becomes necessary. Furthermore, the environmental factors present in Paterson, such as freeze-thaw cycles and moisture exposure, contribute to the deterioration of concrete surfaces and impact the decision-making process regarding when to resurface.

Early Warning Signs of Surface Damage

Typical early warning signs that indicate the necessity of concrete resurfacing include surface peeling/flaking, surface chipping/spalling, which negatively impact both the function and visual appeal of your concrete. The majority of all surface damage begins with small peels/scaling, but it can quickly get out of hand if left unaddressed. When the upper layer of the concrete is damaged, exposed aggregate appears and creates rough surface textures that create safety issues and negatively impact curb appeal. Contractors know how to see these early warning signs and will advise you to resurface prior to having to deal with structural issues.

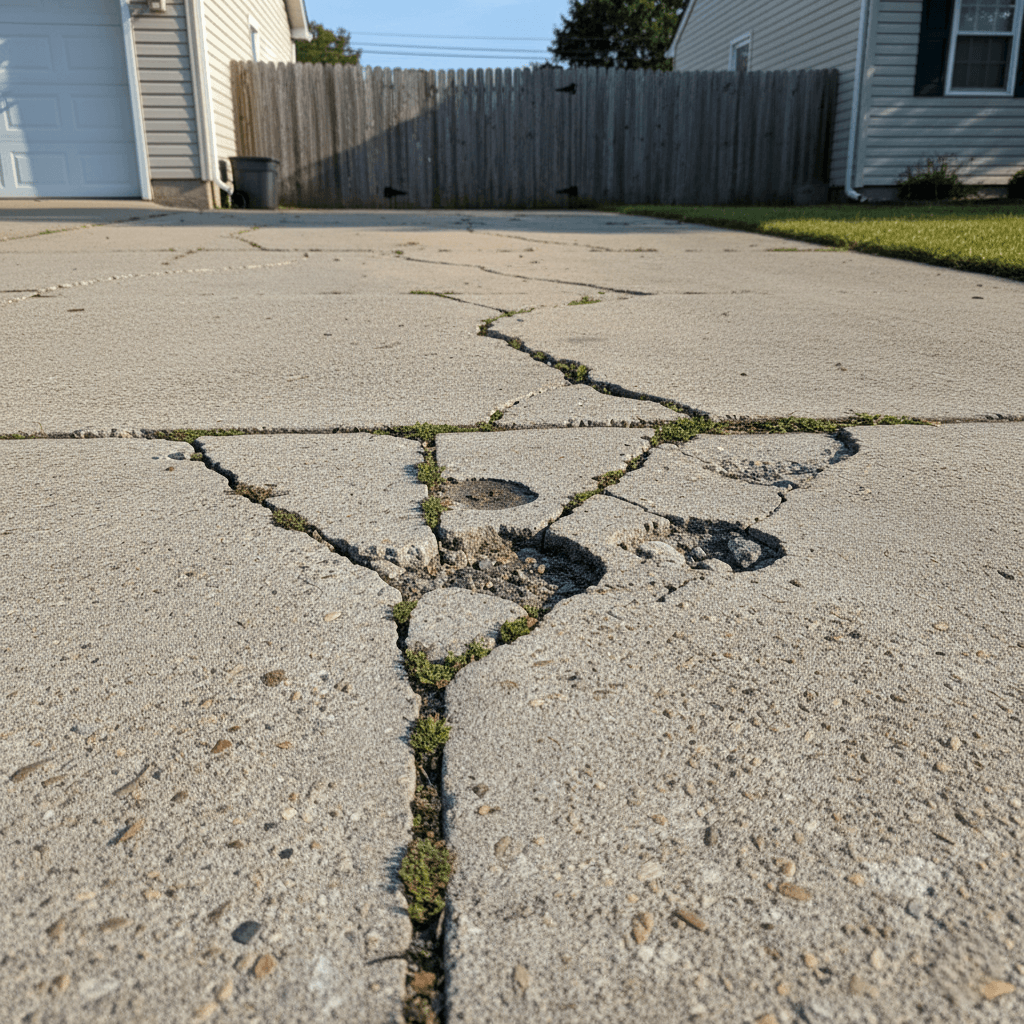

Patterns of Spalling and Scaling

When concrete has spalled due to freeze-thaw cycling, the upper layer of the concrete breaks away, exposing the underlayment and creating a hazardous situation. Freeze-thaw spalling will usually start off as small flakes that continue to grow into much larger pieces of concrete that fall off the main body of the surface. Scaling occurs only on the top layer of concrete initially and allows moisture to seep into the structure, accelerating the breakdown process. Professionals can assess the extent of the spalling and determine if the spalling is in less than one-third of the concrete’s depth, allowing for resurfacing to be a viable option. In addition, by dealing with spalling early on, you avoid water penetrating the structure, potentially compromising the whole structural integrity.

Assessment of Crack Patterns and Structural Integrity

The assessment of cracks in your concrete provides valuable insight regarding the suitability of resurfacing the concrete versus needing to replace it completely. Hairline cracks and surface crazing often perform well with resurfacing applications that seal and protect from additional moisture intrusion. Shrinkage cracks that do not go all the way through the concrete can also be addressed with the right surface preparation and overlay application. Contractors evaluate the width, depth, and distribution of the crack pattern to assess the best course of action to correct the issue. Settlement cracks or structural issues may require additional repair before resurfacing can be completed successfully.

Damage Caused by Load and Wear Patterns

Heavy traffic areas exhibit specific wear patterns that demonstrate when surface deterioration symptoms necessitate resurfacing as opposed to just routine maintenance. Prolonged loading creates compressive damage to the surface, resulting in the formation of depressions and uneven surfaces that affect drainage and aesthetics. Tires, oils, chemicals, and de-icing salt can penetrate surfaces and damage them over time. Evaluating the structural integrity of the base surface will determine whether the area is still structurally sound regardless of the level of surface damage. Resurfacing can restore the ability of the surface to support loads while increasing its resistance to wear and chemical exposure.

Factors Related to Age and Environment

The age of the concrete is an essential factor to consider when evaluating resurfacing options, as 15-20-year-old surfaces generally exhibit extensive wear that warrants restoration. Environmental elements such as moisture, temperature extremes, and chemical exposure found in Paterson’s climate continuously degrade the surface protections. Poorly sealed or maintained surfaces allow for accelerated deterioration that creates a greater urgency and necessity to resurface. Contractors take into consideration the quality of the concrete when it was installed, the construction methods used, and the maintenance history of the concrete when they advise you on when to resurface. Winter conditions create many surface-related issues that can be resolved through comprehensive resurfacing.

Deterioration Caused by Moisture Penetration

Moisture entering cracks, joints, or porously textured surfaces continues to damage the surface, moving from aesthetic concerns to structural concerns. Moisture penetration leads to freeze-thaw damage, which is particularly concerning in locations close to the Great Falls or the Passaic River, where high humidity levels prevail. Also, poorly draining areas surrounding concrete surfaces accelerate moisture-related issues and create a quicker need for resurfacing using protective treatments. Contractors identify moisture-related issues and repair drainage problems before installing resurfacing materials to ensure their long-term success. Additionally, quality moisture barrier products and sealants are key components in successful resurfacing projects.

Safety and Liability Concerns

When surface deterioration creates tripping hazards, slipping hazards, or unstable walking surfaces, immediate attention is required to prevent accidents and liability for property owners. Loose, uneven, and rough surfaces create a higher risk of accidents and potential liability. Additionally, surfaces near pools, walkways, or high-traffic areas pose significant safety risks that resurfacing can effectively resolve. Professional installation ensures the preparation and finishing techniques are properly executed to create safe, slip-resistant surfaces. Additionally, timely resolution of safety-related issues via resurfacing eliminates the possibility of more severe accidents and limits the potential for liability in the long run.

Impact of Property Value and Aesthetics

Curb appeal is severely affected when visible damage, staining, or deterioration exists on the surfaces of your property. Resurfacing is an aesthetically pleasing and cost-effective alternative to replacing the surfaces entirely, thus improving the property’s value and marketability. New surface finishes can enhance home improvements and landscaping initiatives while maintaining uniformity in design themes. Contractors offer a variety of finishing options, including color, texture, and pattern, to improve the appearance of existing surfaces. Well-maintained surfaces of concrete create the standard of care and property values within neighborhoods like Eastside Park and downtown Paterson.

Comparative Cost-Benefit Analysis of Resurfacing vs Replacement

From a financial standpoint, resurfacing is advantageous when the structural integrity of the base surface is intact, but the surface condition necessitates improvement in functionality and aesthetics. Generally, resurfacing is 50-70% less expensive than total replacement while achieving similar aesthetic and functional improvements. Additionally, resurfacing typically has shorter completion times and minimal disruptions as compared to replacement, making it ideal for occupied properties and high-traffic areas. Contractors perform a comparative cost analysis that takes into consideration maintenance needs, expected lifespan, and performance enhancements when determining the best resurfacing solutions. Finally, by avoiding the costs of demolishing and disposing of surfaces, resurfacing offers environmental responsibility and cost-effectiveness.

Expected Long-Term Performance

Resurfacing installations performed correctly will last approximately 10-15 years of satisfactory performance, provided they were applied to a sound substrate and prepared properly. Expected performance includes restoring appearance, improving functionality, and increasing the surface’s resistance to weather and wear-related factors. In addition, quality resurfacing materials and professional installation techniques ensure compatibility with existing concrete and optimal bonding. Contractors can predict the performance of the resurfaced surface, taking into account local climatic conditions, utilization patterns, and maintenance requirements. Additionally, contractors provide warranties and maintenance recommendations to enable property owners to maximize the value and longevity of their resurfacing investment.

Objective Professional Evaluation and Timeliness

Objective professional evaluation provides unbiased assessments of the concrete’s condition, the feasibility of resurfacing, and the optimal time frame to intervene. Seasonal timing impacts the effectiveness of resurfacing, and generally, the best time for resurfacing is during spring and fall when temperatures are moderate and conducive to curing and bonding. Scheduling professional resurfacing allows sufficient preparation time, enables contractors to monitor weather conditions, and ensures proper curing conditions for optimal performance. By coordinating resurfacing with other maintenance tasks, property owners can optimize their efficiency and minimize disruptions to their property.

Requirements for Surface Preparation

Effective resurfacing requires proper surface preparation, and this consists of thoroughly cleaning the surface, crack repair, and evaluating the substrate before overlay application. Professional preparation entails power washing, mechanical abrasion, and chemical cleaning to achieve the optimal bond between the existing and new surfaces. Additionally, conducting proper moisture testing and ensuring the substrate is sound will eliminate premature failures and ensure long-lasting repairs. Contractors understand the local soils and drainage requirements and climatic conditions that influence preparation practices. Contractors frequently require specialized equipment and knowledge to prepare the surface properly and, therefore, justify the need for professional installation rather than attempting to do the job themselves.

Options for Materials and Applications

In today’s world, there are numerous modern options available for concrete restoration, including polymer-modified overlays, decorative resurfacing systems, and specialized repair mortars for specific forms of damage and performance requirements. Contractors select materials based upon the current state of the existing concrete, the proposed use of the surface, desired aesthetic features, and budget constraints. Contractors also understand the importance of selecting materials that are compatible with the existing concrete and will result in a strong bond and long-term performance without delamination. Contractors are knowledgeable of material properties, application requirements, and curing specifications that dictate the success of a project. Advances in resurfacing technologies provide increased durability, aesthetic options, and performance capabilities compared to traditional repair methods.

Standards of Quality and Installation Practices

Contractors adhere to established standards for preparing the surface, mixing materials, applying materials, and curing processes to ensure optimal performance of the resurfaced surface. Quality control measures include testing the substrate, verifying the materials, monitoring the thickness, and completing proper finishing techniques throughout the duration of the installation. Contractors understand the regional climatic conditions and adapt their procedures as needed to meet the demands of Paterson’s environment and seasonal challenges. Adequate documentation and testing will confirm that the resurfacing meets specifications and performance expectations for long-term success. At Paterson Concrete Works, we offer comprehensive concrete resurfacing services that restore both functionality and appearance while extending the life of the surface and enhancing the property value through professional evaluations, quality materials, and professional installation techniques.