Paterson Concrete Slab Installation for Garages & Sheds

Concrete Slab Paterson

The process of creating a concrete slab (for garages or sheds) in Paterson, NJ, involves an understanding of Paterson’s building codes, soil conditions, and loading requirements specific to how you plan to use your structure. Designing a properly sized concrete slab is the most important element of any structure, as it serves as a solid base and meets all of the New Jersey Department of Labor/Division of Codes Enforcement construction standards. Professionals create a design that includes a variety of elements, including garage slab thickness, reinforcement specifications, and drainage requirements that all have a direct effect on the longevity of your structure. In addition to proper design, professional installation methods, and quality materials are required to provide the structural integrity of your foundation to withstand Paterson’s harsh weather conditions, such as freeze-thaw cycles. Finally, professionals assist homeowners in establishing procedures to prevent costly errors and to ensure that their new structures last through time.

Understanding New Jersey Building Code Requirements

The New Jersey State Building Codes are utilized to specify the required minimum thicknesses and strengths of various types of concrete slabs, primarily based upon the intended use of the slab and its structural demands. Residential garage floors located in Paterson shall have a minimum thickness of 3.5 inches and an average compressive strength of 3500 psi. Commercial or heavy-duty applications, such as those that will be subjected to heavy truck or equipment usage, may require a slab thickness of 6 inches or greater, dependent upon anticipated load. Contractors who specialize in installing concrete slabs are aware of these requirements and comply with them by ensuring the slab is designed and installed according to the local building codes.

Permits and Inspections

In general, most concrete slab installations performed in Paterson, NJ, will require both a building permit and inspection to verify that the slab complies with applicable building codes and is structurally sufficient. The permit application procedure requires a detailed plan of the slab, including slab dimensions, thickness specifications, and reinforcing details, submitted to the City for review before issuance of a permit. Inspections will typically take place at multiple stages of construction. The first will be during the excavation phase to ensure the excavation has been completed correctly, the second during the placement of the reinforcing steel, and finally, after the concrete has been placed to ensure the slab complies with the building codes. Before scheduling inspections, contractors must coordinate with the Paterson Department of Construction Code Enforcement (DCCE) to schedule the required inspections and to ensure that the project proceeds smoothly.

Appropriate Slab Thickness Determination and Sizing

Residential garage slab thickness is determined by the intended use of the garage and includes consideration of the expected weight of the vehicles to be stored in the garage. In addition to the primary purpose of providing a parking space for cars, many garages also serve as workshops, storage rooms, and other uses that can generate additional wear and tear on the slab. As a result, garage slabs that are intended to accommodate heavy-duty use, such as trucks, equipment, etc., may require slabs that are 5-6 inches in thickness, while standard residential garage slabs, that are intended to accommodate passenger cars, are typically 4 inches in thickness. In addition to the thickness of the slab, the size of the slab must also be carefully evaluated. For example, small utility sheds that are less than 100 square feet in size may only require 3.5 inch thick slabs, whereas larger sheds that are larger than 100 square feet in size will require larger-thickness slabs for stability. In addition to residential garage slabs and shed slabs, slabs that store heavy equipment or serve as workshop spaces will require the same type of large-thickness slabs that are required for garage slabs. When evaluating a slab for the determination of the proper thickness and size, contractors will consider numerous factors, including wind loads, frost depth, drainage patterns, etc., that affect the slab’s performance. In addition to determining the proper size of the slab, contractors must also evaluate whether there are adequate edge distances and reinforcement in order to ensurelong-termm durability of the slab.

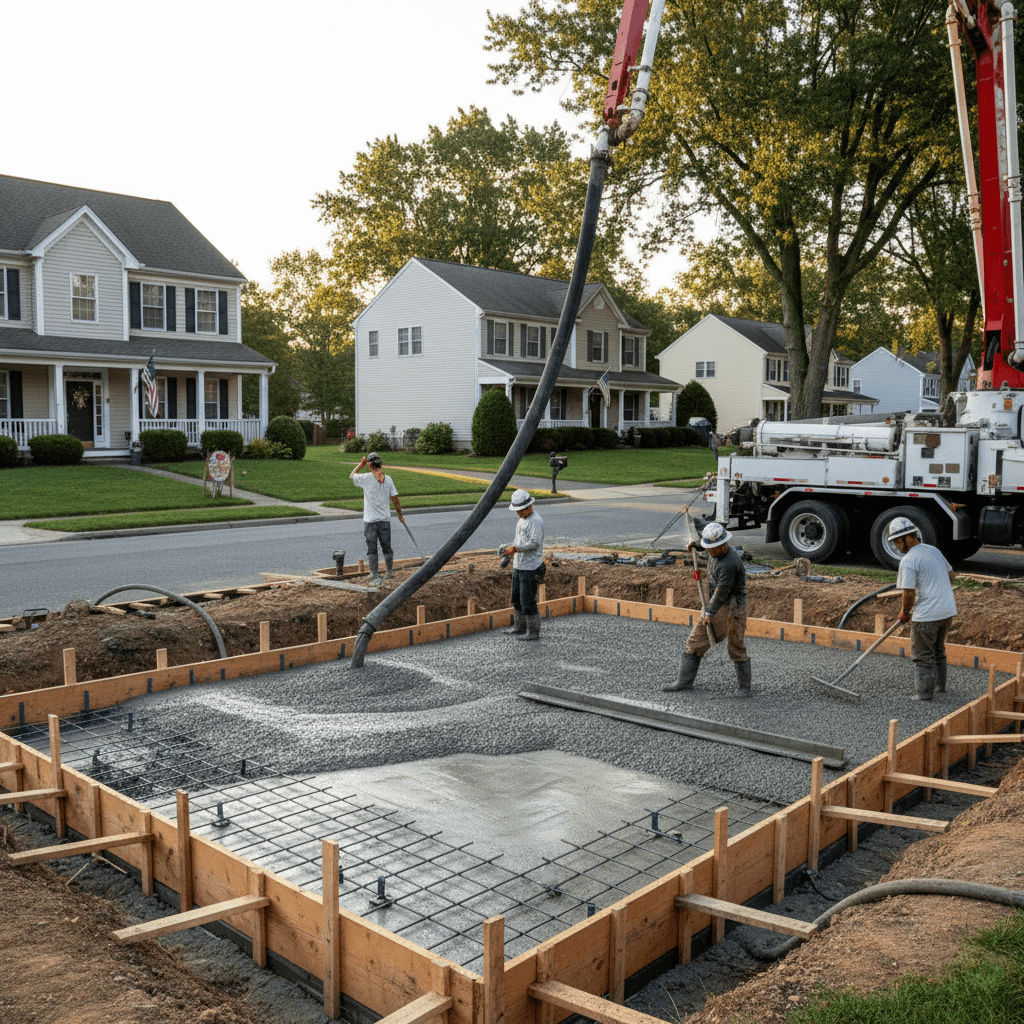

Excavation Site Preparation

Before the installation of a concrete slab, contractors must prepare the excavation site to ensure that it will provide a solid and stable base for the slab. This includes establishing the correct elevation for the slab, creating a proper drainage pattern, and verifying that the sub-grade is stable and capable of supporting the weight of the slab. The depth of the excavation is determined by the thickness of the slab and the amount of base material that is needed underneath the slab to provide a stable base. Typically, the excavation depth is equal to the thickness of the slab plus the thickness of the base material, and is usually in the range of 8-10 inches for a standard installation. Contractors must evaluate the condition of the soil in the area where the excavation is being prepared to determine if it needs to be compacted and to identify any potential problems that may exist. In addition to evaluating the condition of the soil, contractors utilize laser levels and survey equipment to verify that the elevation of the excavation is correct and that the grade is adequate.

Base Materials and Compaction

Base materials are essential for providing a solid and stable base for the concrete slab, as well as for draining water away from the slab. Standard installations use 4-6 inches of compacted gravel or crushed stone to create a solid base for the slab. The use of mechanically compacted base materials is critical for ensuring that they are uniformly dense and eliminate any “soft” areas that may lead to settling or cracking of the slab. Contractors select the proper base material based on what is available locally and the soil conditions in the area. In addition to selecting the proper base material, contractors may install vapor barriers under heated structures to prevent moisture migration through the slab.

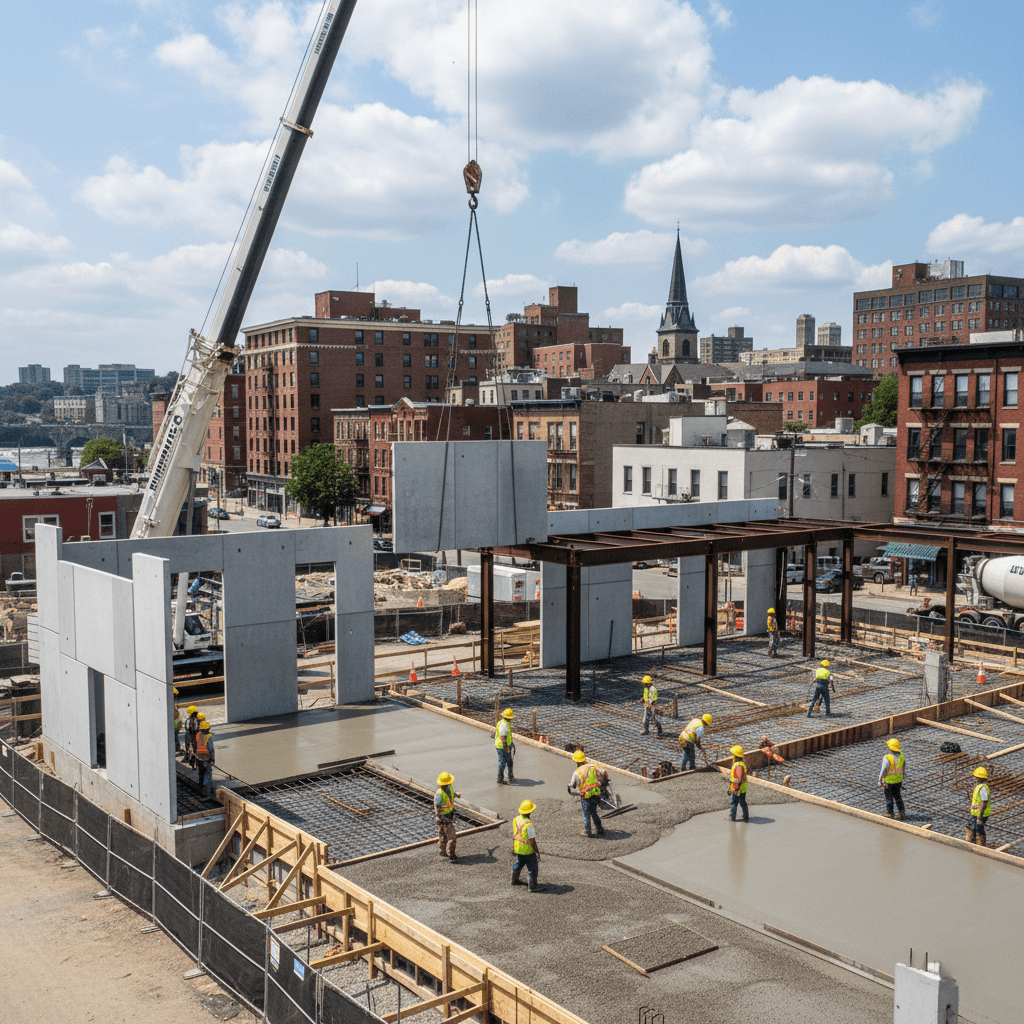

Reinforcement Requirements and Details

The type and extent of reinforcement required for a concrete slab are dependent on the thickness of the slab, the anticipated loads that the slab will be subject to, and the applicable building codes in the area. Wire mesh reinforcement is commonly used in residential garage slabs to control shrinkage cracking and to enhance the overall durability of the slab. Rebar reinforcement may be required for heavier slabs or forheavy-dutyy applications, to provide structural strength to the slab. Contractors know the proper placement requirements for reinforcement, including adequate coverage and support systems that are required to be provided during the placement of the concrete. In certain areas, seismic considerations may require specific reinforcement patterns and connection details.

Control Joints

Control joints are used to manage concrete shrinkage and to prevent random cracking of the slab by providing predetermined locations for cracks to form. Control joints are spaced at a rate of approximately 24-30 times the thickness of the slab, but no further apart than 10-12 feet for residential applications. Contractors must properly seal control joints to prevent water from entering the joint and causing damage due to freeze-thaw cycles. Contractors must install control joints at the proper time to ensure that they are cut cleanly and straightly.

Concrete Mix Design and Ordering

Concrete mix design specifications must satisfy the minimum strength requirements while also providing the necessary workability for the placement and finishing operations. Standard residential garage applications typically require 3,500 psi concrete that contains air entrainment for freeze-thaw resistance in the climate found in New Jersey. Depending on the specific project requirements, contractors may use specialty admixtures to enhance workability, cure characteristics, or surface durability. Contractors must work with their local supplier to obtain the appropriate mix design and to arrange for timely deliveries.

Quantifying and Ordering Concrete

To avoid running short of concrete during the placement operation and to minimize waste and cost overruns, contractors must accurately quantify the amount of concrete required. Contractors calculate quantities by multiplying the length and width of the slab by the thickness of the slab, and converting the resulting volume to cubic yards. To account for waste, spillage, and minor variations in actual thickness, contractors add 5-10% to the calculated volume of concrete. Contractors use precise measurements and coordinate delivery timing to ensure that concrete is delivered continuously and that there are no cold joints. Contractors develop back-up plans for inclement weather and other unexpected events to ensure that projects remain on schedule and meet quality standards.

Preparing Forms and Preparing the Site for Concrete Placement

Proper forms are required to establish the correct dimensions, elevations, and edges of the slab while containing the concrete during the placement and finishing operations. Forms must be straight, level, and securely braced to withstand the pressures exerted by the concrete and to retain the desired shape. In addition to preparing forms, contractors must also establish proper drainage slopes and verify the thickness of the slab to ensure compliance with design specifications and applicable building codes. Before the concrete is delivered, contractors verify all measurements and elevations to avoid costly corrections. Contractors also plan the location of access routes and equipment to facilitate the efficient placement and finishing of the concrete.

Weather Conditions and Timing

Weather conditions play a significant role in determining the best time for placing, curing, and completing concrete slabs, and therefore, contractors must closely monitor weather forecasts to ensure that the best possible conditions prevail for each stage of the project. Weather conditions that are considered ideal for concrete placement, curing, and finishing include temperatures ranging from 50°F to 80°F, low wind speeds, and no precipitation forecasted during the initial curing period. Hot weather requires contractors to implement additional safeguards, such as cooling methods and longer curing protection, to prevent excessive moisture loss. Contractors must plan their projects accordingly to optimize the performance of the concrete.

Placement and Finishing of Concrete

Contractors must perform the placement and finishing of concrete in a manner that will provide a uniform thickness, proper consolidation, and a smooth finish with no voids or defects. Contractors employ systematic placement patterns to prevent segregation and to ensure that the slab thickness remains constant throughout the area. Contractors also employ the proper consolidation methods, either through vibration or screeding, to remove air voids and to ensure that the area adjacent to the reinforcement is filled. Experienced crews will coordinate the placement and finishing of the concrete to ensure quality and timeliness, while working within the constraints of the setting time of the concrete.

Finishing Options and Surfaces

There are several finishing options available to contractors, including broom-finished surfaces, textured surfaces, and smooth trowel-finished surfaces. The choice of finishing option will depend on the desired slip resistance and the aesthetic requirements of the project. Broomed surfaces are typically specified for garage floors to increase the slip resistance of the floor. Smooth trowel finished surfaces are typically used in storage areas and other areas that are used to store heavy equipment because of ease of cleaning. Contractors must begin finishing operations at the proper time to prevent surface defects and ensure long-term durability and performance.

Protecting Cured Concrete

To ensure that the concrete develops the required strength over the critical first 28 days, contractors must protect the cured concrete from adverse weather conditions. Contractors apply curing agents to the concrete immediately after it has been placed and allowed to set. Contractors also cover the cured concrete with plastic sheeting to prevent rapid moisture loss. Contractors must also protect the cured concrete from extreme temperatures, wind, and precipitation to maintain consistent curing conditions throughout the project. Contractors must continually monitor the curing progress of the concrete and implement corrective actions if the curing conditions become unfavorable. Proper curing plays a significant role in determining thelong-termm durability and strength of the concrete.

Restrictions During Curing Period

During the curing period, contractors must restrict the loads on new concrete to prevent damage to the concrete and allow the concrete to develop strength. Contractors typically restrict foot traffic for 1-2 days after the concrete has been placed. Contractors typically restrict vehicle access for 7-14 days after the concrete has been placed, depending on the strength of the concrete and the weather conditions. Heavy equipment or full loading of the slab should not be permitted until the concrete reaches the design strength at 28 days. Contractors must provide specific guidelines to the owners and users of the concrete regarding load restrictions and initial use guidelines for each project.

At Paterson Concrete Works, we provide comprehensive foundation planning and installation services for our customers’ concrete slabs that meet the applicable building codes for the Paterson area, while providing superior performance and durability for garage and shed applications in and around Paterson.