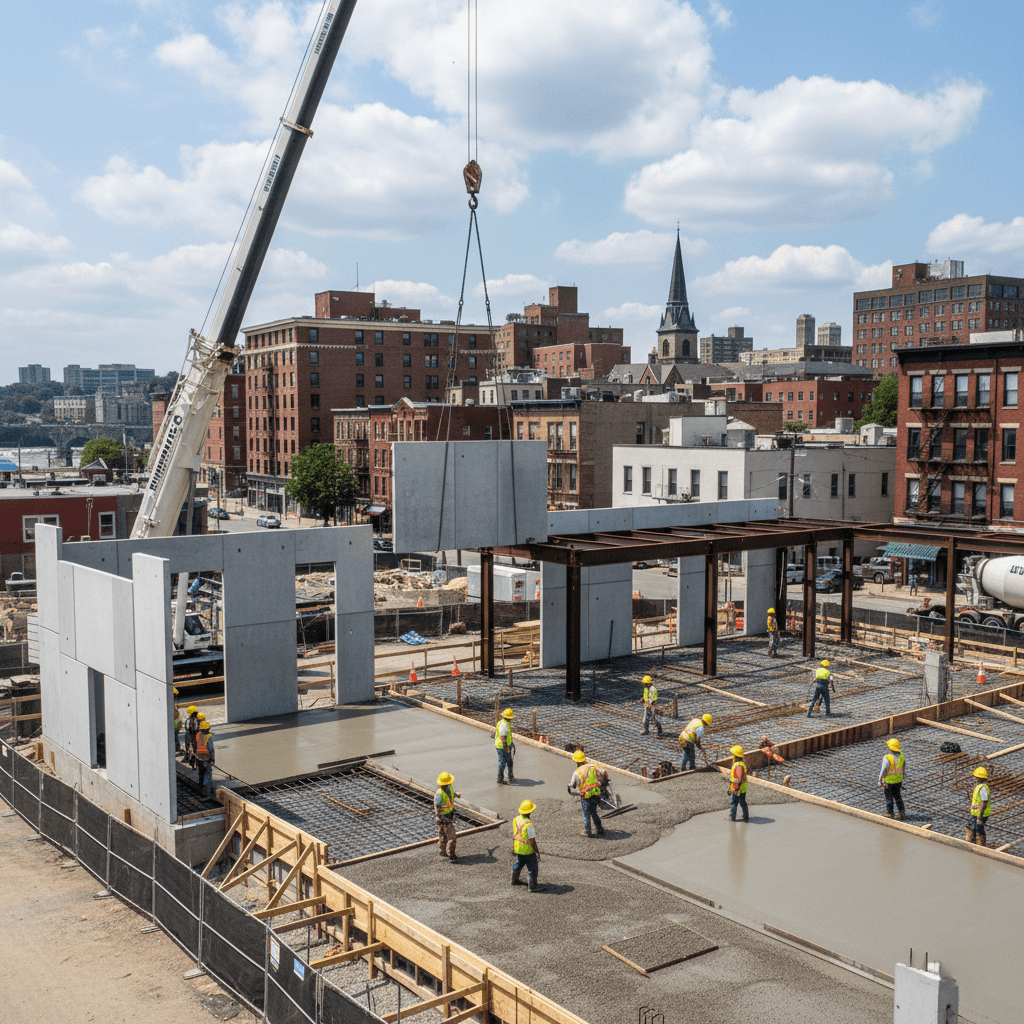

How Weather Impacts Pouring Concrete in Paterson, NJ

Pouring Concrete Paterson

Weather conditions significantly influence concrete placement and curing throughout Paterson, New Jersey. Temperature fluctuations, rainfall patterns, and humidity levels directly affect the strength and durability of freshly placed concrete. Contractors working near landmarks like the Great Falls must carefully monitor local weather conditions before beginning any concrete project. Proper planning helps ensure successful outcomes regardless of seasonal challenges. Understanding these weather impacts allows for better project scheduling and material preparation.

Understanding Paterson’s Climate Challenges

Paterson experiences a diverse climate with temperatures ranging from freezing winters to hot, humid summers. The city’s location in northern New Jersey creates unique challenges for concrete construction throughout the year. Weather conditions such as high ambient temperature, low relative humidity, and high wind speed can impair concrete quality. Local contractors must adapt their techniques based on seasonal variations and daily forecasts. Successful concrete placement requires understanding how these environmental factors interact with fresh concrete.

Cold Weather Concrete Challenges

The American Concrete Institute defines cold-weather concrete work as occurring when temperatures remain below 40°F for more than three consecutive days. Winter projects near Eastside Park require special precautions to prevent concrete from freezing before achieving sufficient strength. Contractors must protect concrete from freezing for the first 24 hours or until it reaches 500 PSI strength. Additionally, any surface contacting concrete during placement should have temperatures above freezing, including reinforcement and formwork.

Winter Protection Methods

Hot water mixing, heated blankets, and windbreaks help prevent freezing during cold-weather concrete placement. Calcium chloride additions up to 2% can accelerate the setting process in cold conditions. Heated enclosures provide additional protection for larger pours throughout the winter months. Moreover, nighttime temperatures dropping below 40°F can cause concrete to freeze, making it prone to chipping and breaking.

Hot Weather Concrete Considerations

Hot weather concrete occurs when temperatures exceed 100°F, though humidity levels also factor into this classification. Summer projects around the Lambert Castle area face accelerated curing that can reduce final concrete strength. High temperatures accelerate cement hydration, potentially resulting in lower 28-day strength than expected. The ACI recommends limiting maximum concrete temperature to 95°F during hot weather conditions.

Managing Heat Effects

Cooling concrete through chilled water, ice, or refrigerated aggregates helps manage temperature during hot weather placement. Shade structures, mist systems, and damp blankets maintain surface moisture during curing. Pouring before 10 AM or after 8 PM avoids the hottest parts of summer days. Furthermore, reducing cement content while maintaining strength requirements decreases heat generation during hydration.

Rain and Moisture Management

Drizzle can actually improve concrete curing, especially when followed by dry weather. However, heavy rainfall during placement creates significant challenges for contractors throughout Paterson. Tarps and plastic sheeting protect fresh concrete from excessive moisture damage. Light rain can interfere with freshly poured concrete for the first four to eight hours after placement.

Precipitation Planning

Scouting sites ahead of time helps identify potential water flow issues from gutters and downspouts. Quick mixing and placement become essential when rain threatens active projects. Fast, powerful mixing equipment allows crews to complete pours before weather conditions deteriorate. Additionally, covering materials and having contingency plans prevents weather-related delays.

Paterson Building Code Requirements

Building inspectors in Paterson enforce the Uniform Construction Code and issue permits for all construction projects. Construction permits require plan review fees equal to 20% of the total permit cost. Applicants must provide certification that all municipal taxes and assessments are current before permit issuance. The building code requires a minimum 2500 PSI compressive strength for footings and 3000 PSI for foundation walls.

Permit Compliance

Building permits are required for structural, electrical, HVAC, and plumbing projects to ensure safety compliance. The Planning and Zoning Division reviews construction plans and permit applications for zoning compliance. Weather-related delays can affect permit timelines and inspection schedules. Therefore, contractors must coordinate with city officials when weather impacts construction schedules.

Professional Weather Monitoring

Successful concrete contractors maintain constant weather awareness throughout the project duration. Monitoring concrete temperature both at arrival and after 45-60 minutes guides necessary adjustments. Digital thermometers help track concrete temperatures during placement and early curing stages. Maximum-minimum thermometers monitor curing box temperatures during extreme weather periods.

Equipment and Technology

Modern concrete temperature monitoring systems provide real-time data for quality control decisions. Wireless sensors track internal concrete temperatures throughout the curing process. Weather stations help predict upcoming conditions that might affect planned pours. Additionally, smartphone apps provide hourly forecasts for better project scheduling around the Garret Mountain Reservation area.

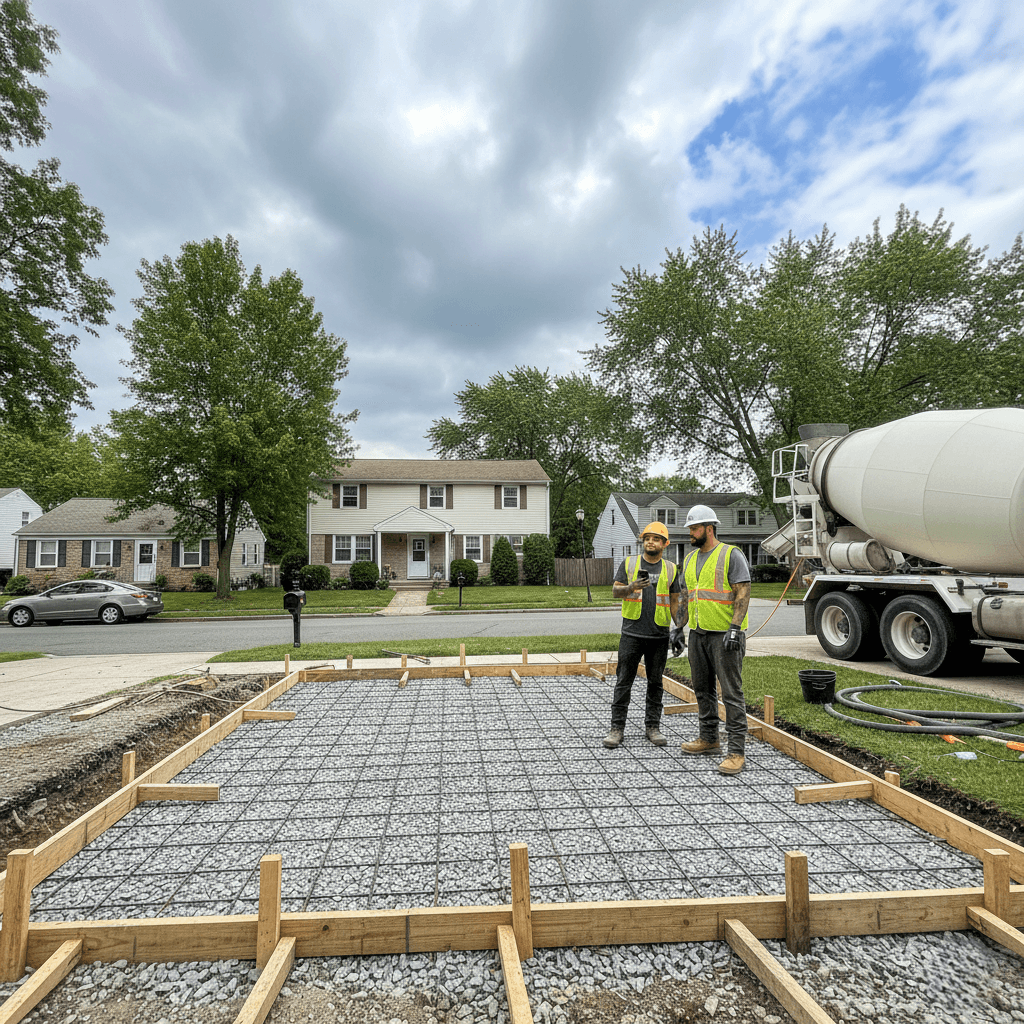

Seasonal Project Planning

Mild spring and fall temperatures between 50-60°F provide ideal conditions for concrete placement. Summer projects require early morning or evening scheduling to avoid peak heat. Winter work demands additional materials, equipment, and protection measures. Checking weather forecasts before starting helps ensure appropriate conditions for concrete placement. Proper weather planning ensures successful concrete projects throughout Paterson’s diverse climate conditions. Our team at Paterson Concrete Works monitors local weather patterns to schedule optimal placement times for residential and commercial projects. We understand how Paterson’s unique climate affects concrete performance and adjust our techniques accordingly for durable, long-lasting results.