Understanding Prefabricated Concrete

Prefabricated concrete involves manufacturing components in controlled factory environments before transporting them to construction sites for assembly. This method ensures consistent quality through standardized production processes and optimal curing conditions. Factory production eliminates weather-related delays that commonly affect site construction in New Jersey’s variable climate. Quality control measures include rigorous testing and inspection protocols throughout the manufacturing process. The controlled environment allows for precise mixing ratios, proper curing temperatures, and systematic reinforcement placement.

Prefab Manufacturing Process

The prefabrication process begins with detailed engineering designs that specify exact dimensions and structural requirements. Specialized molds create components ranging from wall panels and floor slabs to structural beams and columns. High-strength concrete mixes incorporate advanced additives that enhance durability and performance characteristics. Reinforcement placement follows precise specifications with quality inspections at each stage. Curing occurs under optimal temperature and humidity conditions that maximize concrete strength development.

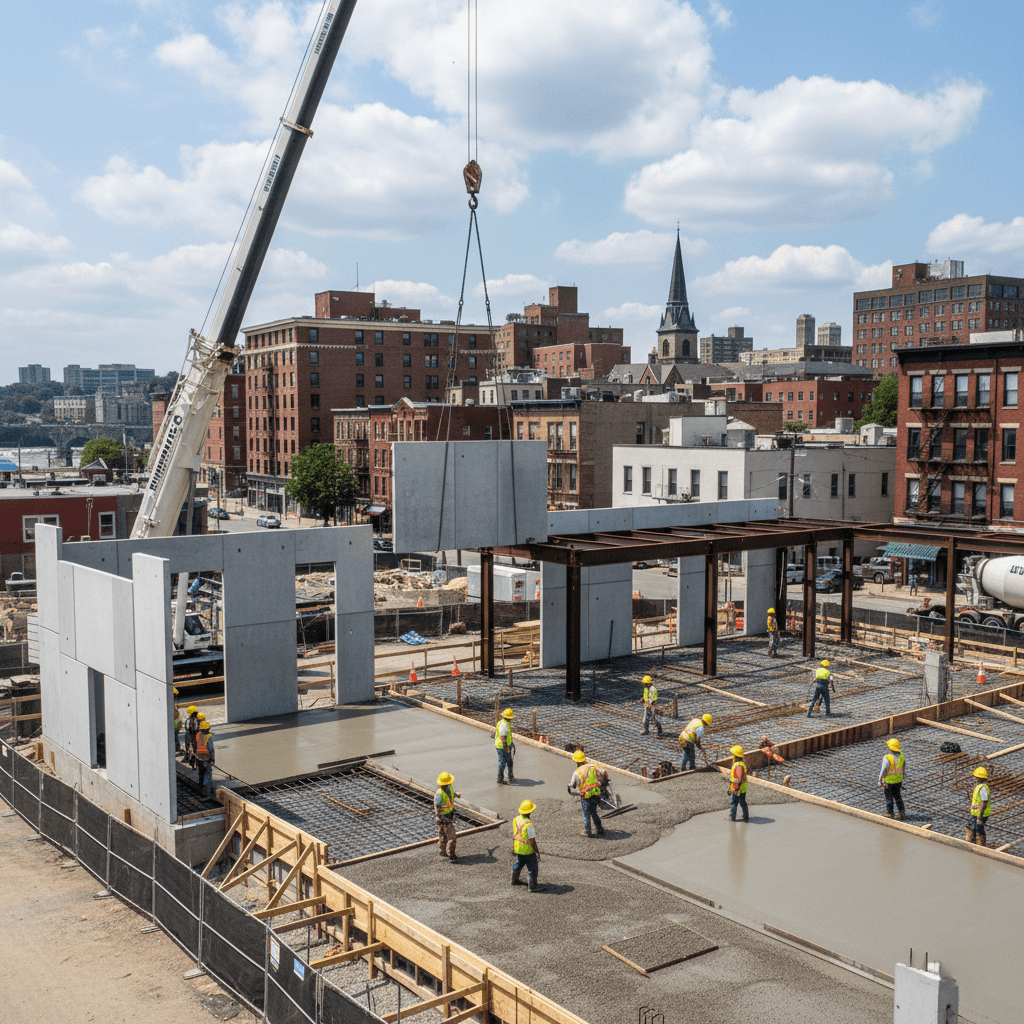

Transportation and Installation

Specialized transportation equipment delivers prefabricated components to Paterson construction sites when needed for installation. Crane operations require careful coordination to position heavy concrete elements safely and accurately. Installation teams use precision equipment to ensure proper alignment and structural connections. The assembly process typically requires fewer on-site workers compared to cast-in-place methods. Professional installation ensures structural integrity and compliance with local building codes.

Cast-in-Place Concrete Methods

Cast-in-place concrete involves pouring mixed concrete directly into forms at the construction site, where it cures in its final position. This traditional method offers maximum flexibility for custom designs and site-specific adaptations. On-site mixing allows for adjustments based on immediate conditions and project requirements. The monolithic nature of cast-in-place construction creates seamless connections between structural elements. Professional contractors manage the entire process from form preparation through final finishing and curing.

Site Preparation and Formwork

Proper site preparation includes excavation, grading, and utility coordination to create optimal working conditions. Formwork systems use engineered panels and supports that shape the concrete to exact specifications. Reinforcement placement requires skilled workers who position rebar according to structural drawings. Quality inspections verify proper spacing, coverage, and connections before

concrete placement begins. Professional formwork ensures accurate dimensions and smooth finishes for exposed surfaces.

Concrete Placement and Finishing

Ready-mix concrete trucks deliver material directly to placement locations using pumps or conveyor systems. Skilled finishers work quickly to level, smooth, and texture surfaces while concrete remains workable. Proper consolidation eliminates air voids and ensures complete reinforcement encasement. Timing coordination becomes critical as concrete workability decreases with temperature and time. Professional placement techniques guarantee structural integrity and aesthetic quality.

Advantages of Prefabricated Concrete

Quality control represents the primary advantage of prefabricated concrete through factory production standards. Consistent manufacturing conditions produce uniform strength and durability characteristics throughout all components. Advanced testing protocols verify structural properties before components leave the factory. Precision manufacturing achieves tight tolerances that ensure proper fit during assembly. Professional quality assurance programs exceed typical site construction standards.

Speed and Efficiency Benefits

Prefabricated components arrive ready for immediate installation, eliminating on-site curing time requirements. Parallel production allows manufacturing to occur simultaneously with site preparation activities. Assembly typically requires 40% less time compared to equivalent cast-in-place construction. Reduced construction schedules minimize business disruption and accelerate occupancy timelines. Weather independence ensures consistent progress regardless of seasonal conditions.

Cost Effectiveness

Factory efficiency reduces labor costs through assembly-line production techniques and skilled specialization. Bulk material purchasing provides cost advantages over smaller site-delivered quantities. Reduced construction time minimizes financing costs and overhead expenses during the building process. Quality consistency prevents costly repairs and callbacks associated with construction defects. Long-term durability reduces maintenance expenses throughout the building’s operational life.

Advantages of Cast-in-Place Concrete

Design flexibility stands as the greatest advantage of cast-in-place concrete for unique architectural requirements. Custom shapes, curves, and complex geometries become achievable through adaptable formwork systems. On-site modifications accommodate field conditions and last-minute design changes effectively. Architectural concrete finishes create distinctive appearances that enhance building aesthetics. Integration with other building systems occurs seamlessly during the construction process.

Structural Performance

Monolithic construction creates continuous structures without joints that could compromise long-term performance. Superior resistance to seismic forces results from the integral nature of cast-in-place systems. Excellent bond strength between concrete and reinforcement ensures optimal structural behavior. Custom reinforcement patterns address specific load conditions and architectural requirements. Professional engineering ensures compliance with all applicable building codes and standards.

Site Adaptability

Large or complex components that exceed transportation limits become feasible through on-site construction. Irregular sites and tight access conditions favor cast-in-place methods over prefabricated alternatives. Integration with existing structures occurs more easily through cast-in-place connections. Utility coordination and embedment placement adapt to field conditions during construction. Immediate problem-solving capabilities address unforeseen site conditions effectively.

Cost Comparison Analysis

Initial material costs favor prefabricated concrete for large-scale projects with repetitive elements. Labor expenses typically run lower for prefab installation compared to the skilled trades required for cast-in-place work. Transportation costs add to prefab projects but often get offset by reduced on-site labor requirements. Project financing benefits from shorter construction schedules that reduce carrying costs and accelerate revenue generation. Total project costs depend on specific requirements, scale, and complexity factors unique to each development.

Long-term Value Considerations

Maintenance requirements remain minimal for both methods when properly installed and designed. Prefab quality control often results in fewer callbacks and warranty issues over time. Cast-in-place flexibility may provide advantages for future modifications and expansions. Energy efficiency benefits result from superior insulation integration possible with prefabricated systems. Resale values reflect the quality and functionality of either method when professionally executed.

Application Suitability

Warehouse and distribution facilities benefit from prefabricated components that provide large, clear spans and quick construction. Office buildings often favor cast-in-place methods for complex architectural features and custom layouts. Retail developments are chosen based on design requirements and construction timeline constraints. Industrial facilities prioritize durability and functionality that both methods can provide effectively. Mixed-use projects may incorporate both approaches to optimize different building areas.

Project Scale Considerations

Large projects with repetitive elements favor prefabricated approaches that maximize factory efficiencies. Small to medium projects often find cast-in-place methods more cost-effective due to setup requirements. Complex architectural designs typically require cast-in-place flexibility for unique elements. Renovation projects near downtown Paterson may favor cast-in-place methods for better integration with existing structures. Professional evaluation determines the optimal approach for specific project characteristics.

Environmental and Sustainability Factors

Prefabricated concrete reduces waste generation through precise manufacturing and material optimization. Transportation impacts must be weighed against reduced on-site disruption and faster construction. Factory production enables better recycling of materials and more efficient resource utilization. Cast-in-place methods reduce transportation energy but may generate more construction waste. Both approaches can incorporate sustainable materials and design features that enhance environmental performance.

LEED and Green Building Considerations

Factory production facilitates the incorporation of recycled materials and sustainable concrete mixes. Reduced construction time minimizes environmental disruption during the building process. Energy-efficient designs become easier to implement through prefabricated building envelope systems. Local material sourcing benefits both methods, depending on the proximity of suppliers and manufacturers. Professional green building consultation optimizes environmental performance regardless of the chosen method.

Quality Control and Inspection

Prefabricated components undergo comprehensive testing and inspection before leaving the manufacturing facility. Cast-in-place quality depends on skilled field supervision and proper testing protocols during construction. Third-party inspection services verify compliance with specifications and building codes for both methods. Material testing includes strength verification, durability assessment, and performance validation. Professional quality assurance programs ensure consistent results that meet project requirements.

Performance Standards

Structural performance specifications remain consistent regardless of the construction method chosen. Fire resistance, durability, and safety requirements apply equally to both prefab and cast-in-place systems. Industry standards govern manufacturing processes, installation procedures, and final inspection criteria. Professional engineering oversight ensures compliance with all applicable codes and regulations. Ongoing monitoring and maintenance preserve performance characteristics throughout the building’s service life. Professional expertise guides Paterson businesses toward optimal commercial concrete solutions that balance performance, cost, and timeline requirements. Our experienced team at

Paterson Concrete Works provides comprehensive evaluation services that consider all project factors and local conditions to recommend the most effective approach for your specific needs.