Advantages of Concrete Flooring

Concrete flooring offers exceptional durability that can withstand decades of use without showing significant wear. The polished surface resists scratches, dents, and impact damage that would affect other flooring materials. Properly installed and maintained, polished concrete can last 50 to 100 years with minimal upkeep requirements. The inherent strength of concrete makes it ideal for high-traffic areas and homes with pets or children. Professional installation ensures the surface achieves optimal hardness levels between 3,000 and 6,000 pounds per square inch.

Low Maintenance Requirements

Daily maintenance involves simple sweeping and occasional mopping with pH-neutral cleaners designed for concrete surfaces. The non-porous surface prevents stains from penetrating deep into the material when spills are cleaned promptly. Unlike hardwood or carpet, polished concrete requires no waxing, refinishing, or periodic replacement of worn areas. Regular maintenance costs remain minimal compared to other flooring options that need frequent professional cleaning or restoration. The smooth surface eliminates dust accumulation and allergen buildup common with carpeted floors.

Cost-Effectiveness and Value

Installation costs range from $3 to $15 per square foot, making concrete flooring competitive with mid-range to high-end alternatives. Utilizing existing concrete slabs reduces material costs and installation time for many Paterson homes. The long lifespan eliminates the need for replacement or major repairs that other flooring types require. Energy efficiency improves through the thermal mass properties of concrete, which help regulate indoor temperatures. Property values increase with well-designed, polished concrete installations that appeal to modern buyers.

Design Flexibility and Aesthetics

Modern concrete polishing techniques offer numerous finish options from matte to high-gloss surfaces. Decorative treatments include acid stains, integral colors, and aggregate exposure for customized appearances. The seamless surface creates visual continuity in open floor plans popular in Paterson’s renovated homes. Stamped patterns and colored concrete can mimic natural stone, tile, or other premium materials at lower costs. The reflective surface enhances natural light throughout living spaces, reducing lighting costs.

Environmental Benefits

Polishing existing

concrete slabs utilizes materials already present in the home, reducing waste and environmental impact. The manufacturing process produces fewer volatile organic compounds compared to synthetic flooring materials. Concrete’s longevity reduces the frequency of replacement and disposal associated with shorter-lived flooring options. Local sourcing of concrete materials minimizes transportation costs and environmental footprint for Paterson residents. The thermal mass properties contribute to energy-efficient heating and cooling systems.

Disadvantages of Concrete Flooring

The hard surface provides no cushioning underfoot, which can cause fatigue during extended standing periods. Falls on concrete surfaces pose higher injury risks, particularly for elderly residents and young children. The unforgiving nature means dropped items are more likely to break upon impact with the floor. Standing for long periods on concrete can contribute to joint pain and discomfort. Area rugs and mats help mitigate some comfort issues, but add maintenance requirements.

Temperature and Comfort Concerns

Concrete floors feel cold to the touch, especially during Paterson’s winter months without supplemental heating. Radiant floor heating systems can address temperature issues, but increase installation costs by $2 to $5 per square foot. The thermal conductivity that provides energy benefits also makes the surface uncomfortable for barefoot walking. Humidity levels can affect the perceived temperature and comfort of concrete surfaces. Seasonal temperature variations require additional heating considerations in bedrooms and living areas.

Sound and Acoustic Issues

Hard concrete surfaces amplify noise and create echoes in rooms with high ceilings or minimal furnishings. Footsteps, dropped objects, and furniture movement generate more noise than with softer flooring materials. Sound transmission to lower levels increases in multi-story homes near Pennington Park neighborhoods. Acoustic treatments or area rugs help reduce noise levels but add to the overall project cost. Open floor plans popular in modern homes can become uncomfortably loud with concrete flooring.

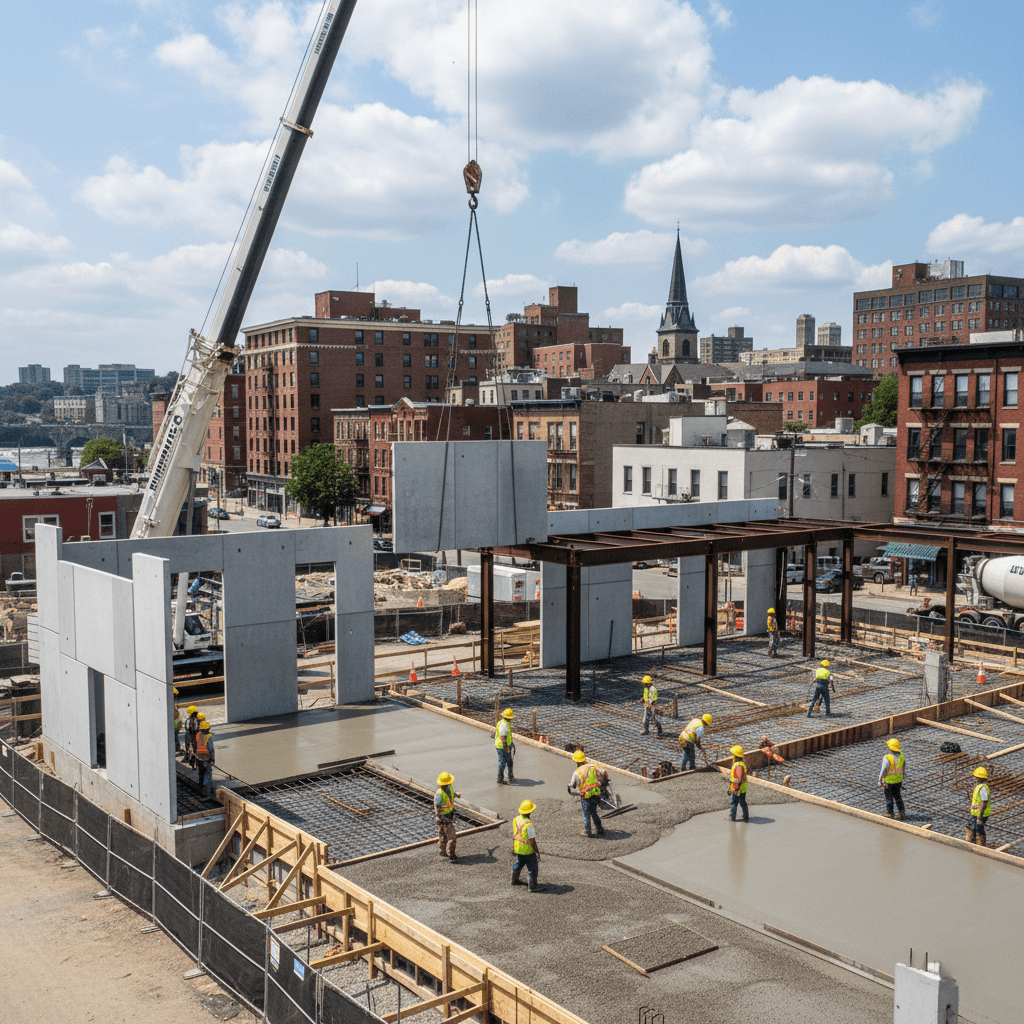

Installation Considerations

Professional installation requires specialized equipment and expertise to achieve proper polish levels and finish quality. The existing concrete slab condition affects the final appearance and may require repairs or overlays. Installation timing must account for curing periods and multiple grinding stages that extend project duration. Dust control during grinding requires proper ventilation and containment measures throughout the home. Furniture removal and temporary living arrangements may be necessary during the installation process.

Quality and Preparation Requirements

The existing concrete quality directly impacts the final polished appearance and durability of the finished floor. Cracks, stains, or surface imperfections may remain visible after polishing and become permanent design elements. Moisture issues in basement or ground-level installations require proper vapor barriers and drainage solutions. Structural assessments ensure the existing slab can support polishing equipment and daily use requirements. Proper preparation accounts for 30-40% of the total installation timeline and cost.

Maintenance and Long-term Care

Periodic resealing every 2-5 years maintains the protective surface and preserves the polished appearance. Deep cleaning with specialized equipment removes accumulated dirt and restores the original luster. Stain prevention requires immediate cleanup of acidic substances that can etch the surface permanently. Professional maintenance extends the floor’s lifespan and maintains warranty coverage from contractors. Regular inspections identify potential issues before they require costly repairs or refinishing.

Repair and Refinishing Options

Surface scratches and minor damage can often be polished out during regular maintenance cycles. Major repairs may require matching custom colors or patterns, which can be challenging and expensive. Localized refinishing blends with existing surfaces but may show slight variations in appearance. Complete refinishing restores the original appearance but requires significant time and expense. Proper maintenance prevents most issues that would require major repairs or surface restoration.

Cost Analysis and Investment

Initial installation costs compete favorably with premium hardwood, natural stone, and high-end tile options. Long-term ownership costs remain lower due to minimal maintenance and no replacement requirements. Radiant heating installation adds upfront costs but provides ongoing comfort and energy savings. Professional maintenance every few years costs less than refinishing hardwood or replacing worn carpet. The resale value addition often exceeds the initial investment for well-executed installations. Professional installation ensures optimal results and long-term satisfaction with polished concrete flooring in Paterson homes. Our team at

Paterson Concrete Works specializes in residential concrete flooring that combines durability, aesthetics, and value for homeowners throughout the city. We understand the unique challenges of working in historic neighborhoods and provide customized solutions that enhance your home’s appeal while meeting your practical needs.